Ceramic-to-Metal

Our team of technical experts in the field of ceramic-to-metal seals at our facility in Moissy-Cramayel (only 30 minutes south-east of Paris), formerly known as VERMETAL, has developed a unique expertise in the production of highly engineered brazed assemblies.

These hermetic ceramic-to-metal seals have been designed for the most extreme applications that exceed the limits of conventional materials and solutions: Electrical insulation, high temperature, high pressure, high voltage, high-vacuum HV and ultra-high vacuum UHV reliability, cryogenics or corrosive environments.

The main markets served for hermetic feedthroughs and ceramic-to-metal seals are aircraft, aerospace, defense, nuclear, physical research, electron and vacuum tubes, also known as valves, such as X-ray tubes for medical imaging or materials science.

Solcera offers material combinations including (.pdf)

- Insulators: 96 to 99% alumina, zirconia, sapphire, quartz, CaF₂ , MgF₂ , spinel

- Metals: FeNi, FeNiCo, copper, Inconel, stainless steel, molybdenum, nickel, platinum, titanium

- Brazing materials for low and high temperatures

- Additional treatments as gold plating, glazing

- Welding operations: TIG, electron beam EB or laser

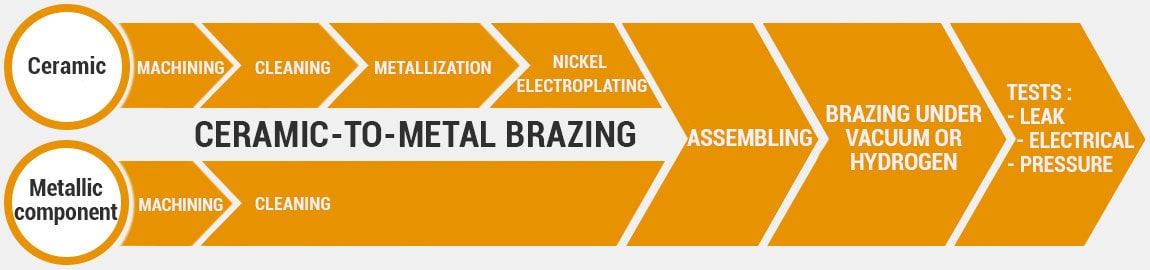

Solcera uses two main processes making an alloying reaction possible

- Ceramic-to-metal assembly with prior moly-manganese MoMn metallization, fired under controlled atmosphere, followed by nickel plating and sinter-firing for conventional brazing processes with alloys such as AgCu.

- Assembly using active metal brazing alloys. These alloys contain an “active” element such as Ti reacting with oxygen. An active Ti-based metallization is deposited either by brush or by PVD sputtering followed by active brazing processes.

Ceramic-to-metal brazing

Ceramic-to-metal or glass-to-metal assembly ?

| TECHNICAL SPECIFICATIONS | CERAMIC | GLASS |

|---|---|---|

| High-pressure applications | Good | Excellent |

| Metallic materials compatibility | Wide | Narrow |

| Lifetime | Excellent | Excellent |

| Helium leak-proof | 10-¹² mbar.l/s/cm² | 10-¹² mbar.l/s/cm² |

| Insulation and electrical performances | Excellent | Good |

| Temperature resistance | Excellent | Good |

| Geometric accuracy | Excellent | Good |

| Corrosion resistance | Excellent | Good |

| Assembly mechanical strength | Good | Excellent |

Solcera has a strong know-how in both assembly technologies. Our experts will guide you in choosing the solution that better meets your needs.

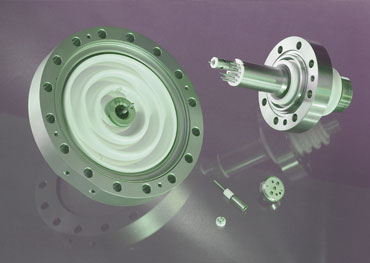

Examples of products :

- Hermetic ultra-vacuum UHV and high-voltage feedthroughs

- Multipin and coaxial connectors

- Brazed assemblies for pressure sensors, distance sensors

- Brazed windows viewports

- Flash lamps for high power laser amplifiers

- X-ray tubes

Ceramic-to-Metal

A project, do you need information or advice ?

Read moreContacts

- ZI N°1 - Rue de l'industrie

- 27000 EVREUX

- +33 (0)2 32 29 42 00

- 83 Rue Marcelin Berthelot

- 77550 MOISSY-CRAMAYEL

- +33 (0)1 64 13 61 10

- Contact